Digital Printing Fundamentals Explained

Wiki Article

Rumored Buzz on Digital Printing

Table of ContentsGet This Report on Digital PrintingRumored Buzz on Digital PrintingHow Digital Printing can Save You Time, Stress, and Money.

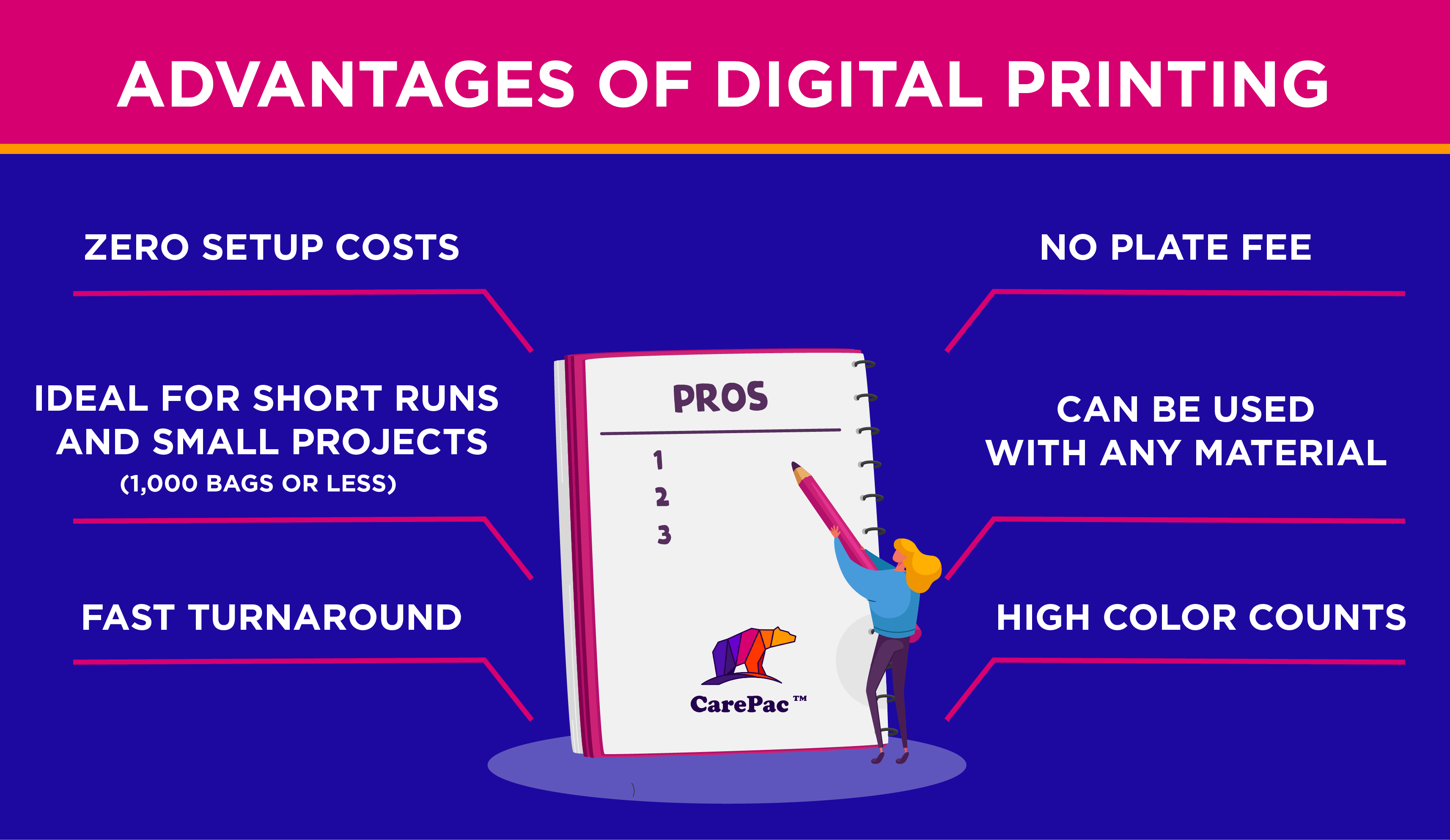

The fluid ink complies with the substratum with an electrostatic fee, making sure vivid colours and sharp information. Digital printing also requires very little arrangement. Contemporary lithographic modern technology has lowered arrangement times to around 15 minutes, electronic printing still leads to comfort with its near-instant readiness. Additionally, digital prints dry quickly, unlike lithographic prints, which call for 2-3 hours to completely dry. This removes smearing dangers and the demand for drying shelfs. Here are the crucial ways in which digital printing sustains greener methods: One of the substantial environmental advantages of electronic printing is lowering waste. Conventional printing methods, like lithographic printing, often waste significant quantities of paper and ink during the setup phase. Digital printing eliminates the requirement for plates and various other consumables, lowering waste throughout the manufacturing procedure. A few of one of the most typical applications include: Digital printing is excellent for producing calling card, leaflets, posters and other marketing products. It enables fast turnaround times and cost-effective manufacturing, especially for organizations with smaller sized print runs. Digital printing is increasingly used in the product packaging industry to create unique, custom-designed packaging.

Digital printing machine get rid of the demand for these plates, dramatically lowering configuration prices. Digital printing presses can incorporate variable information into your prints, which enables for highly personalized advertising and marketing products (Digital Printing). By personalizing your advertising and marketing products, you can enhance involvement with potential consumers and improve the possibilities of transforming them into real consumers

Digital printing machine supply superb shade consistency and accuracy, causing better prints. With digital printing, you can be sure that the color of your prints next will certainly be regular from one print task to the following. Several years back, numerous customers did not approve direct-injection electronic printing due to the fact that the high cost. The acquisition cost of an established electronic printing equipment is at the very least 150%of the typical printing and dyeing devices, which raises the.

Getting The Digital Printing To Work

In order to avoid deterioration of the nozzle, the ink for electronic printing is a lot more expensive than the ink for standard printing, and added ink purification is needed during the printing process. In electronic inkjet printing, the pattern is directly printed on the fabric, eliminating the plate making in rotary display printing. Yes, are more pricey than standard printing inks, however the electronic printing procedure can save ink usage.

Today, the digital direct-injection printing equipment has actually gone from proofing to the stage of medium-sized and large-sized manufacturing. Both printing houses and brand owners are conscious of the advancement capacity of electronic look at this website printing, and are willing to increase investment in digital printing. Digital printing is much more cost-efficient for short print runs because it needs much less pre-press activities and much less arrangement than balanced out printing.

Variable information printing, such as direct mail with customized codes and addresses, is preferably matched for electronic printing. Digital fast printing just needs four steps of design, testimonial, printing and binding to get every little thing done. Digital quick printing has an unrivaled benefit: print on demand.

Report this wiki page